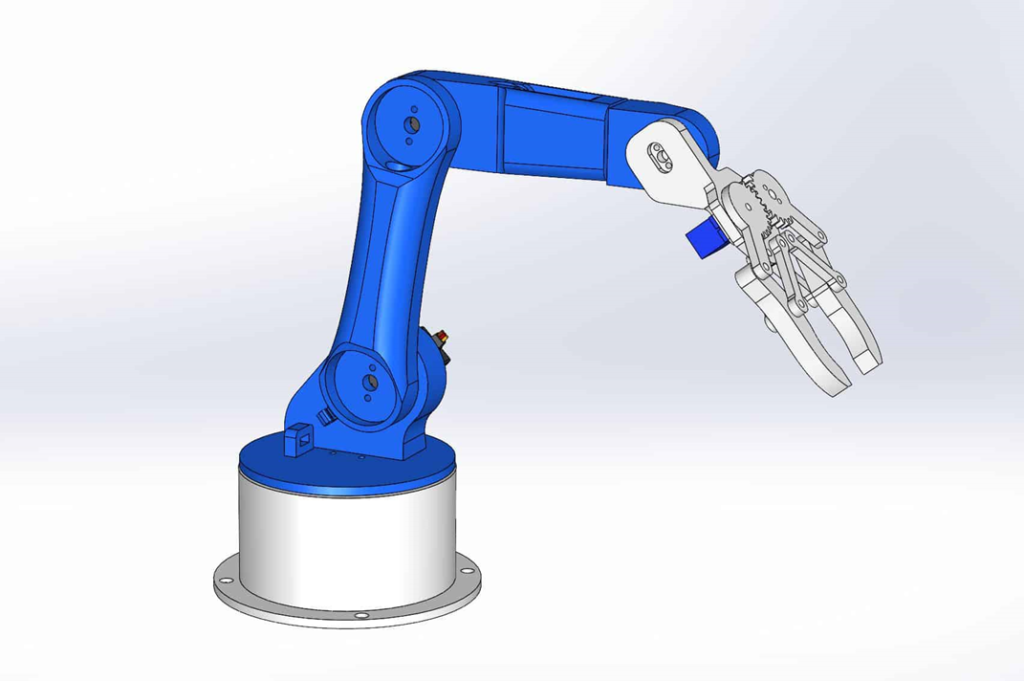

6DOF Robotics Arm Documentation

A 6DOF (Six Degrees of Freedom) robotic arm is a type of robotic arm that can move in six different ways, providing a high level of flexibility and precision. The “degrees of freedom” refer to the independent movements it can make, typically in three rotational axes (pitch, yaw, and roll) and three translational axes (movement along the X, Y, and Z axes).

- Base Rotation (Yaw): This allows the base of the arm to rotate, providing the ability to move in the horizontal plane.

- Shoulder Movement (Pitch): This controls the arm’s upward and downward movement.

- Elbow Movement (Pitch): This moves the forearm closer to or farther from the body of the arm.

- Wrist Pitch: This moves the wrist up and down.

- Wrist Roll: This rotates the wrist around its own axis.

- Wrist Yaw: This rotates the wrist side to side, allowing the end effector (e.g., gripper or tool) to adjust orientation.

Reference Material

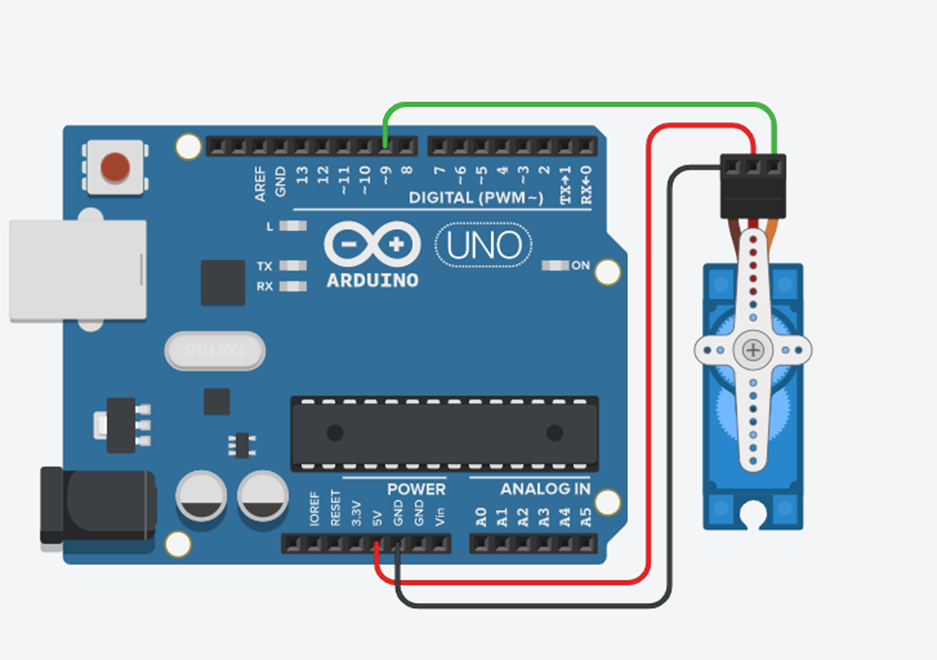

Servo Motor Interfacing with Arduino Uno

Program:

#include <Servo.h>

Servo myservo;

void setup()

{

myservo.attach(9);

}

void loop() {

myservo.write(180);

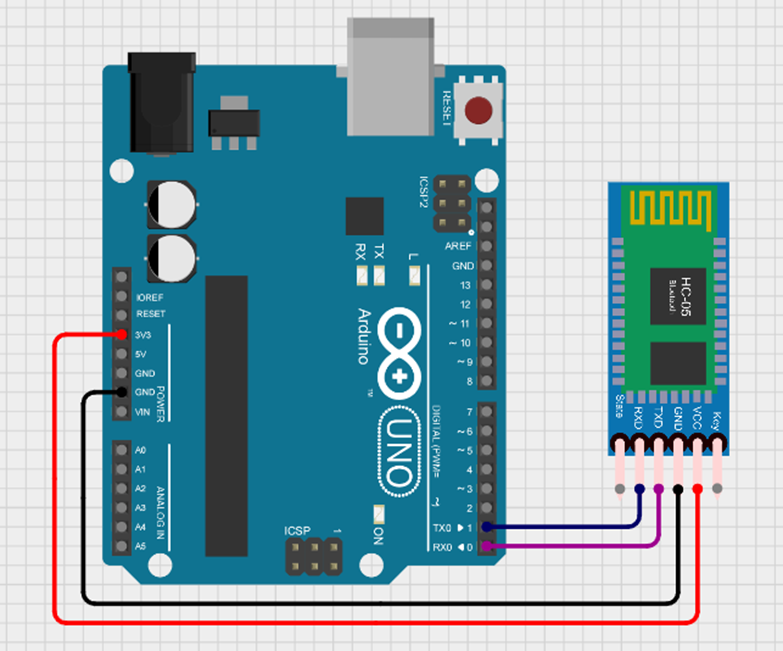

}Bluetooth interfacing with Arduino

Program:

char cmd;

void setup() {

Serial.begin(9600);

}

void loop() {

if(Serial.available()>0){

cmd = Serial.read();

Serial.println(cmd);

}

}Bluetooth Application for controlling Robot Arm

Android App Link – download app

ios App Link – download app

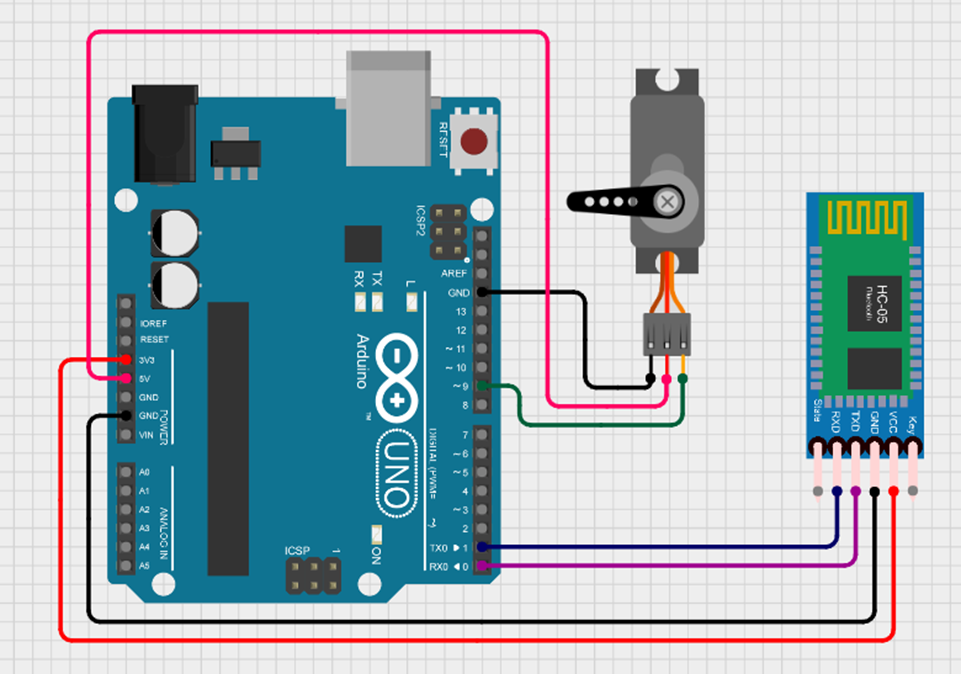

Servo Motor & Bluetooth interfacing with Arduino Uno

Program:

#include<Servo.h>

Servo gate;

char cmd;

void setup() {

Serial.begin(9600);

gate.attach(9);

}

void loop() {

if(Serial.available()>0){

cmd = Serial.read();

Serial.println(cmd);

if(cmd=='B'){

gate.write(90);

}

if(cmd=='b'){

gate.write(0);

}

}

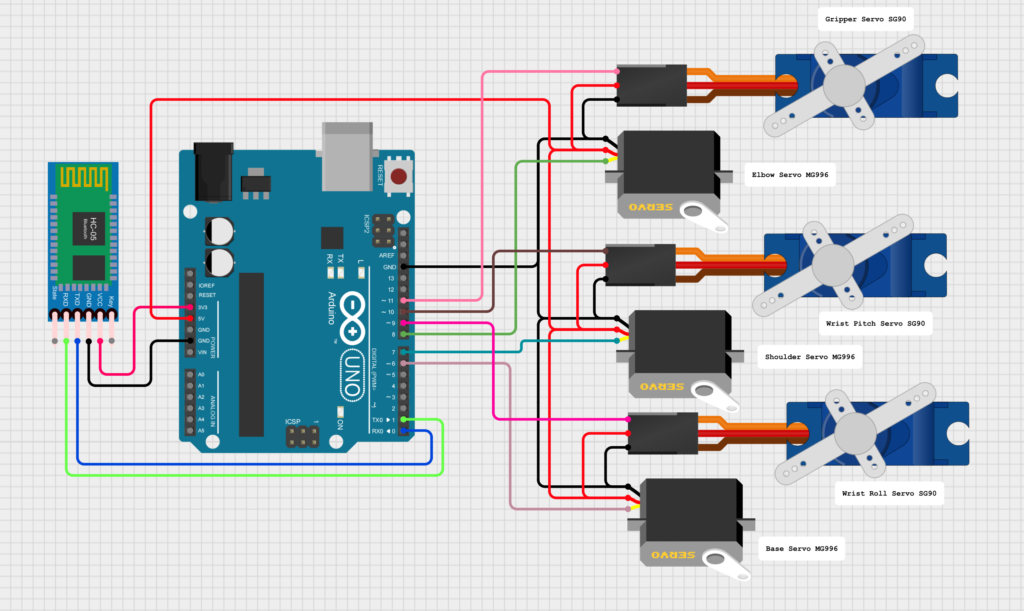

}Final Ble Control Robotic Arm Circuit Diagram

Final Ble Control Robotic Arm Code

#include <Servo.h>

// Define Servo objects

Servo baseServo, shoulderServo, elbowServo, wristRollServo, wristPitchServo, gripperServo;

// Define pins and initial angles

const int basePin = 6, shoulderPin = 7, elbowPin = 8, wristRollPin = 9, wristPitchPin = 10, gripperPin = 11;

int baseAngle = 90, shoulderAngle = 90, elbowAngle = 90, wristRollAngle = 90, wristPitchAngle = 90, gripperAngle = 95;

// Step delay for smooth motion

const int stepDelay = 20;

// Function to move servo smoothly

void moveServo(Servo &servo, int ¤tAngle, int targetAngle) {

if (currentAngle < targetAngle) {

for (int angle = currentAngle; angle <= targetAngle; angle++) {

servo.write(angle);

delay(stepDelay);

}

} else {

for (int angle = currentAngle; angle >= targetAngle; angle--) {

servo.write(angle);

delay(stepDelay);

}

}

currentAngle = targetAngle;

}

void setup() {

// Attach all servos and set initial positions

baseServo.attach(basePin);

baseServo.write(baseAngle);

shoulderServo.attach(shoulderPin);

shoulderServo.write(shoulderAngle);

elbowServo.attach(elbowPin);

elbowServo.write(elbowAngle);

wristRollServo.attach(wristRollPin);

wristRollServo.write(wristRollAngle);

wristPitchServo.attach(wristPitchPin);

wristPitchServo.write(wristPitchAngle);

gripperServo.attach(gripperPin);

gripperServo.write(gripperAngle);

// Initialize serial communication

Serial.begin(9600);

}

void loop() {

if (Serial.available()) {

char command = Serial.read(); // Read the received command

Serial.println(command); // Debugging: print received command

// Control each servo based on the command

switch (command) {

case 'B': // Base Clockwise

moveServo(baseServo, baseAngle, min(baseAngle + 10, 180));

break;

case 'b': // Base Anticlockwise

moveServo(baseServo, baseAngle, max(baseAngle - 10, 0));

break;

case 'S': // Shoulder Clockwise

moveServo(shoulderServo, shoulderAngle, min(shoulderAngle + 5, 120));

break;

case 's': // Shoulder Anticlockwise

moveServo(shoulderServo, shoulderAngle, max(shoulderAngle - 5, 60));

break;

case 'E': // Elbow Clockwise

moveServo(elbowServo, elbowAngle, min(elbowAngle + 10, 180));

break;

case 'e': // Elbow Anticlockwise

moveServo(elbowServo, elbowAngle, max(elbowAngle - 10, 0));

break;

case 'R': // Wrist Roll Clockwise

moveServo(wristRollServo, wristRollAngle, min(wristRollAngle + 10, 180));

break;

case 'r': // Wrist Roll Anticlockwise

moveServo(wristRollServo, wristRollAngle, max(wristRollAngle - 10, 0));

break;

case 'W': // Wrist Pitch Clockwise

moveServo(wristPitchServo, wristPitchAngle, min(wristPitchAngle + 10, 180));

break;

case 'w': // Wrist Pitch Anticlockwise

moveServo(wristPitchServo, wristPitchAngle, max(wristPitchAngle - 10, 0));

break;

case 'G': // Gripper Open

moveServo(gripperServo, gripperAngle, min(gripperAngle + 5, 180));

break;

case 'g': // Gripper Close

moveServo(gripperServo, gripperAngle, max(gripperAngle - 5, 95));

break;

default:

Serial.println("Invalid Command");

break;

}

}

}Pick & Place Robot Code:

#include <Servo.h>

// Define Servo objects

Servo baseServo, shoulderServo, elbowServo, wristRollServo, wristPitchServo, gripperServo;

// Define pins and initial angles

const int basePin = 6, shoulderPin = 7, elbowPin = 8, wristRollPin = 9, wristPitchPin = 10, gripperPin = 11;

int baseAngle = 90, shoulderAngle = 90, elbowAngle = 90, wristRollAngle = 90, wristPitchAngle = 90, gripperAngle = 95;

// Step delay for smooth motion

const int stepDelay = 20;

// Function to move servo smoothly

void moveServo(Servo &servo, int ¤tAngle, int targetAngle) {

if (currentAngle < targetAngle) {

for (int angle = currentAngle; angle <= targetAngle; angle++) {

servo.write(angle);

delay(stepDelay);

}

} else {

for (int angle = currentAngle; angle >= targetAngle; angle--) {

servo.write(angle);

delay(stepDelay);

}

}

currentAngle = targetAngle;

}

void setup() {

// Attach all servos and set initial positions

baseServo.attach(basePin);

baseServo.write(baseAngle);

shoulderServo.attach(shoulderPin);

shoulderServo.write(shoulderAngle);

elbowServo.attach(elbowPin);

elbowServo.write(elbowAngle);

wristRollServo.attach(wristRollPin);

wristRollServo.write(wristRollAngle);

wristPitchServo.attach(wristPitchPin);

wristPitchServo.write(wristPitchAngle);

gripperServo.attach(gripperPin);

gripperServo.write(gripperAngle);

}

void loop() {

// No operation in loop as movements are delay-based

// Pick operation

delay(3000);

moveServo(baseServo, baseAngle, 100); // Move base to pick position

moveServo(shoulderServo, shoulderAngle, 120); // Lower shoulder

moveServo(elbowServo, elbowAngle, 40); // Extend elbow

moveServo(gripperServo, gripperAngle, 95); // Close gripper (Pick object)

delay(1000);

moveServo(shoulderServo, shoulderAngle, 90); // Lift object

moveServo(elbowServo, elbowAngle, 60);

// Place operation

delay(3000);

moveServo(baseServo, baseAngle, 160); // Move base to place position

moveServo(shoulderServo, shoulderAngle, 120); // Lower shoulder

moveServo(elbowServo, elbowAngle, 40); // Extend elbow

moveServo(gripperServo, gripperAngle, 180); // Open gripper (Release object)

delay(1000);

moveServo(shoulderServo, shoulderAngle, 90); // Return to home position

moveServo(elbowServo, elbowAngle, 60);

}

Applications:

- Industrial Automation: Manufacturing tasks like assembly, welding, and packaging.

- Research and Development: Prototyping new robotic movements or advanced control algorithms.

- Medical Field: Assisting in surgeries and rehabilitation.

- Robotics Education: A common platform for teaching robotics and control systems.